ARTICLE REF – ART013

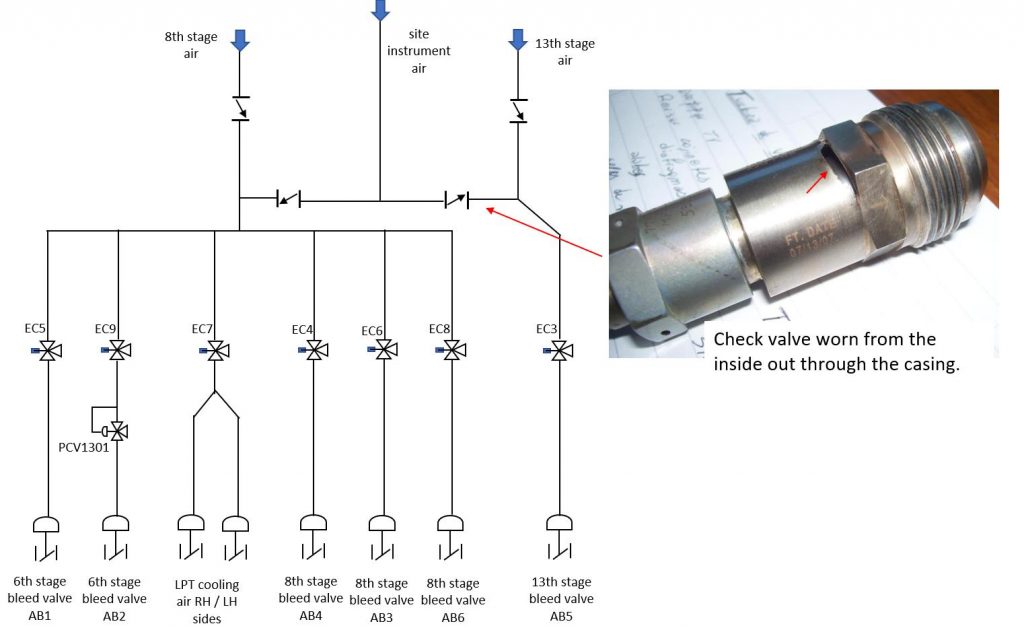

Bleed air check valves

These check valves can rattle about when the unit is shut down and supplying site instrument air to maintain the bleed valves closed. The bleed valves are closed when the heater is supplying hot air to prevent oxidation of the internal of the turbine. When the relative humidity instrument (RH014) is greater then 75% the engine heater (EH1201) is energized. Bleed valve solenoids are energized to close the bleed valves. It is unusual to find the bleed valve solenoids de-energized, not sure why. On this site there were several check valve failures. There are condenser fans for a steam turbine alongside the units, so there is high humidity permanently in the area which keep the heaters on most of the time. It is very quick and easy to check the vales and it might be a good idea to include this inspection as part of the turbine maintenance.

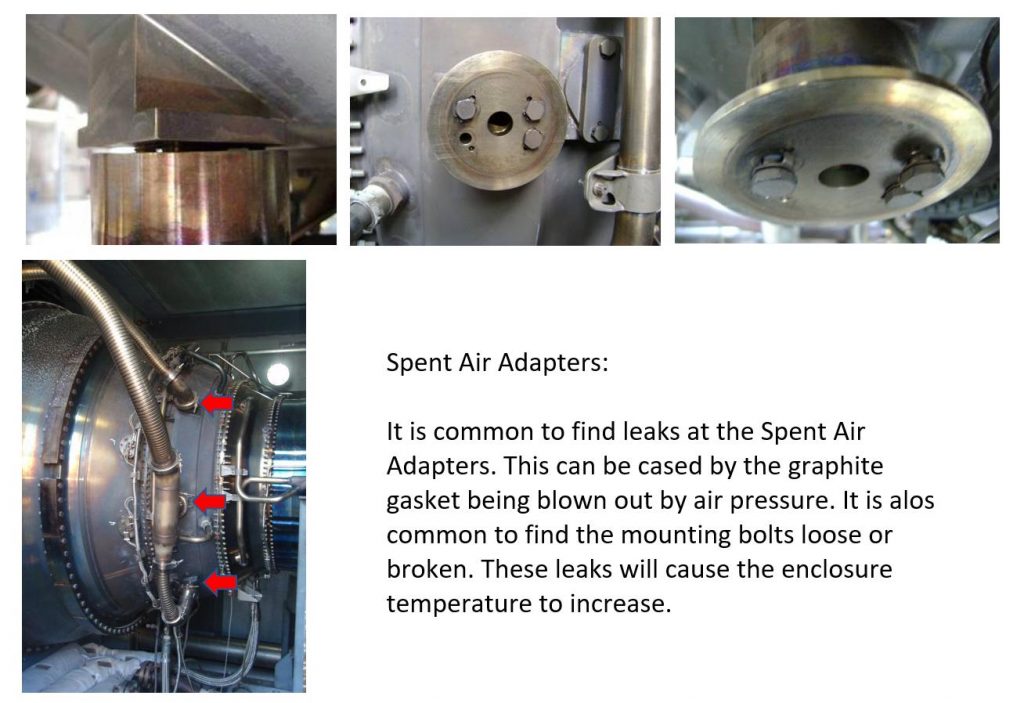

Spent air adapters

An inspection of the Spent Air Adapters should also be part of the maintenance plan. They can quickly be checked by hand to see of they are loose, or any sign of the gasket being blown out. The air exiting the exhaust casing is hot and will increase the temperature of the enclosure.

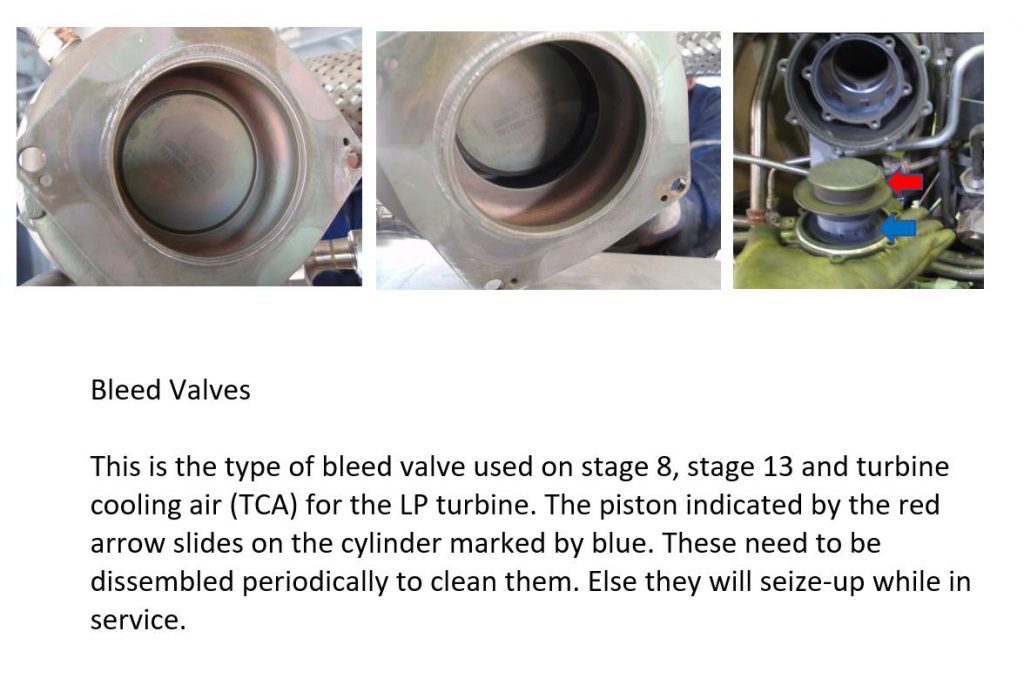

Bleed valve cleaning

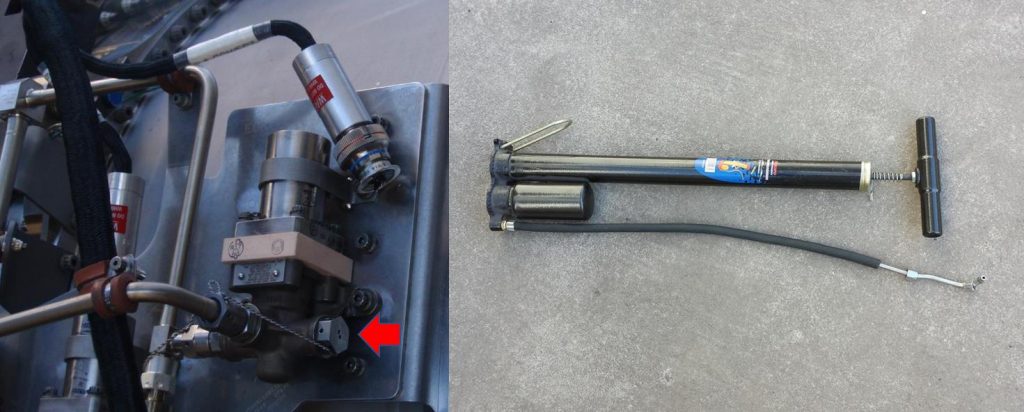

Bleed valve checker tool

To make this tool you need a hand pump, an elbow ¼ NPT x ¼ OD and about 20 cm. of ¼ tubing. Before using the pump is necessary to eliminate the “check valve action” of the pump piston so it is double acting. Pushing the rod to make pressure closing the valve, and pulling to makes a vacuum opening the valve. To test any valve, you must remove the vent cap of the solenoid and connect the elbow of the pump. The solenoid must be de-energized to do the test. Actuate the pump quickly will open and close the valve to the limits of travel. The sound that the valve makes gives you an indication of how dirty it is (the closing sound is higher). The idea for this tool was thanks to Enrique Boffi – Argentina.

Bleed Valve Solenoid ( PN 801942 ) repair

This is a document which describes and shows with photos the solenoid being dismantled and reassembled again. Originally these solenoids were mounted with the electric connection at the bottom. This caused condensation in the air lines to accumulate and corrode the solenoid. SB 98B27 can be referenced for information on that modification. Thanks to Sergoio Stoessel – Argentina for this document. If you would like a copy of this document please send me an email.